Hyundai and Kia are looking to combine battery-pack cases with vehicle structural components for greater packaging efficiency.

In a patent filing published by the United States Patent and Trademark Office (USPTO) on Nov. 14, 2024, and first submitted by the automakers to that agency Oct. 26, 2023, Hyundai and Kia discuss having a vehicle’s floor double as the upper panel of a battery pack case. This would make better use of available space, allowing more modules to be fitted, the automakers argue.

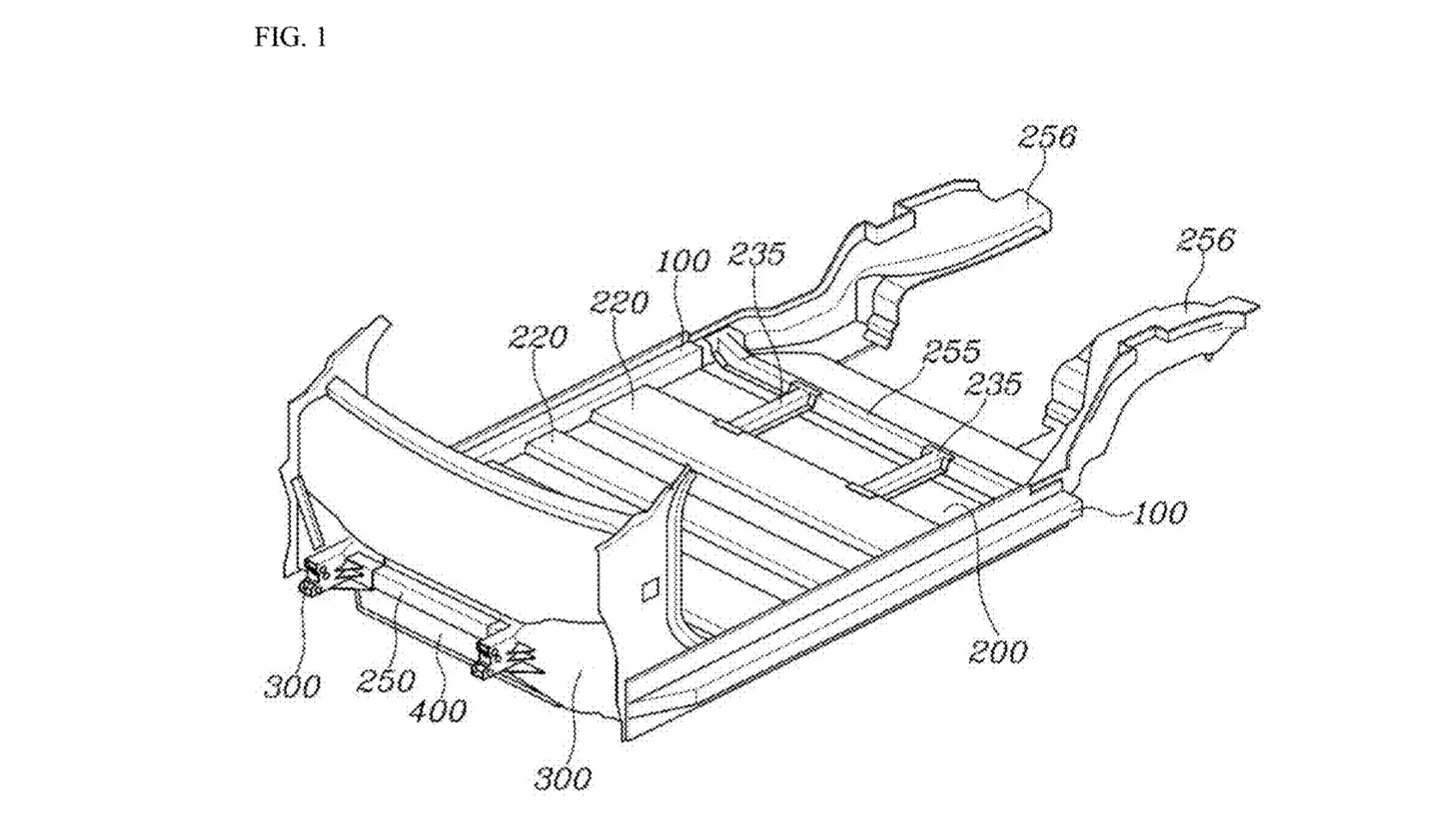

Hyundai and Kia battery case floor patent image

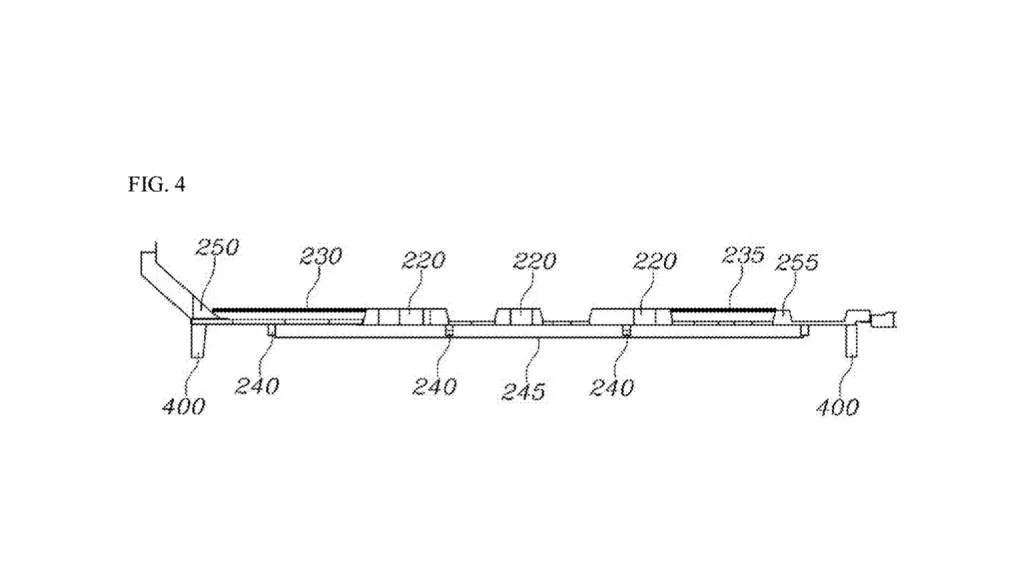

This would more closely integrate the battery pack with the vehicle’s structure, several major components of which would attach to the floor panel that also serves as the upper battery case panel. These include side sills and cross members, with some of the latter potentially blended with the floor panel by using an extrusion fabrication method.

Battery modules would be placed underneath the floor, potentially in voids not occupied by crossmembers, with front and rear barriers protecting the pack and integrated with the side sills, the automakers say in the filing.

Hyundai and Kia battery case floor patent image

Other companies have also explored structural battery packs. Tesla outlined its own design at its 2020 Battery Day, claiming at the time that a structural battery would offer a 10% mass reduction, a potential 14% range increase, and 370 fewer parts with battery cells essentially incorporated as part of a honeycomb against the underside of the vehicle floor. Startup Canoo made structural batteries part of its unique skateboard platform, but retained modules while still claiming a 90-pound weight reduction.

Last year, Chinese startup Neta Auto said it was working with battery supplier CATL to ditch battery packs and integrates cells directly with a vehicle’s chassis, taking CATL’s cell-to-pack tech one step further. Beyond that, researchers have also looked at using body panels as batteries, although the various structural battery pack concepts are likely closer to production.

Read the full article here