Massachusetts-based Factorial has introduced a process for manufacturing solid-state battery cells, in the size range that electric vehicles can use, that is also close to what can be used for mass production.

The company has been providing test cells to automakers, but on Thursday announced that it had scaled sample cells to an “automotive-relevant” 40-amp-hour capacity and was using a dry-coating process that it claims maximizes energy density while minimizing operating costs and the environmental impact of battery production.

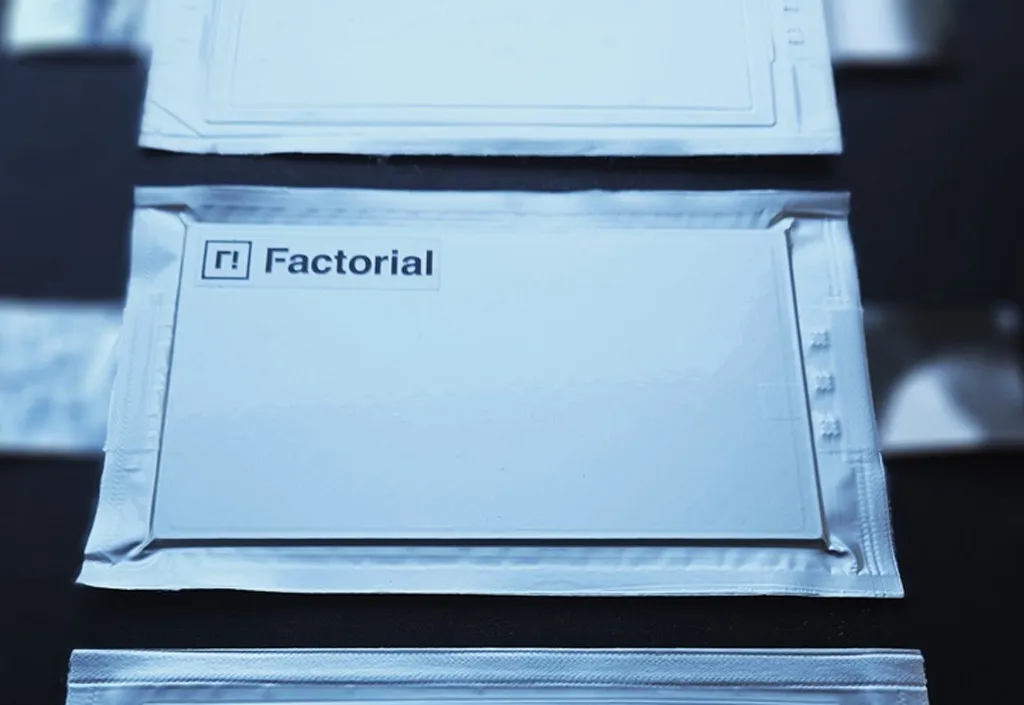

Factorial solid-state cells

The dry coating process eliminates all hazardous solvents, Factorial said in a press release. The coating process is also less energy-intensive than conventional manufacturing processes, Factorial claims, while the solid-state chemistry eliminates the need for a formation process used with liquid-electrolyte chemistries for a further reduction in energy use.

Factorial noted that it used customized equipment at its Massachusetts development center to establish the dry coating process, but that provides a template for manufacturing at proper battery factories, like the one Factorial announced in 2023. And in terms of durability, Factorial claims smaller prototype cells have already reached over 2,000 charge and discharge cycles.

Rendering of Dodge Charger Daytona test bed for Factorial solid-state battery cells

Factorial counts Hyundai, Mercedes-Benz, and Stellantis among its investors. Earlier this year it announced that cells developed in collaboration with Mercedes could boost range by up to 80% through greater energy density. More recently, Factorial confirmed that Stellantis will test its solid-state cells in a fleet of Dodge Charger Daytona EVs starting in 2026.

Other automakers have shown interest in solid-state batteries. Toyota announced earlier this year that it planned to begin manufacturing them in 2026 or soon after, albeit likely in low volumes. But Factorial appears to be making progress toward manufacturing solid-state batteries in commercially relevant volumes.

Read the full article here